At Keewaydin Farm, constant improvement is not only the family motto, it’s the smart way to farm.

Les Pike has embraced the latest technologies on Keewaydin Farm in Stowe, but he’ll tell you he’s only keeping up with family tradition. His grandfather, who started the farm back in 1921, bought the first Ford Harvester in Vermont back in the 40’s, and the family always chopped their hay, instead of baling it like every other dairy farmer in the area.

“Guess it runs in the family that we like to try new things,” says Les.

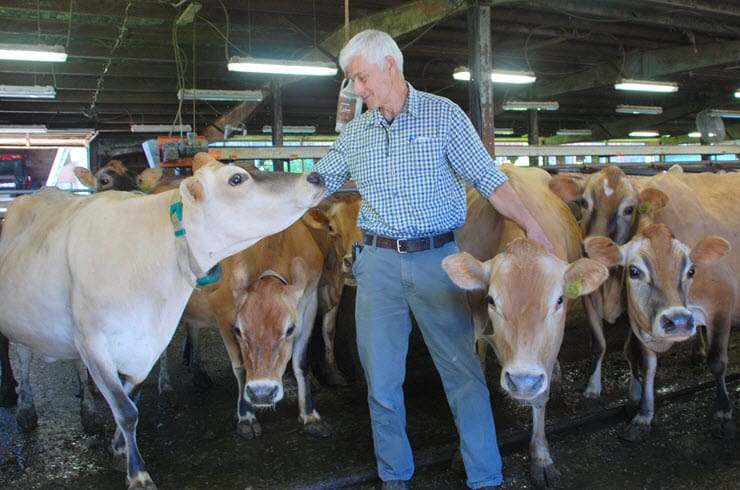

Les and Claire Pike operate a 141-head registered Jersey farm with their children, Dan and Suzi, emphasizing herd health and innovation.

In 2010, the Pikes installed a methane digester that uses cow manure to generate electricity, saving them $400 per month. The digester also provides two useful byproducts: the liquid by-product is used as fertilizer on the fields, and the solid byproduct as cow bedding (it’s 100% bacteria free, and costs $750 less a month than the kiln-dried sawdust previously used).

Les Pike holds cow bedding that is a byproduct of the anaerobic digester process to turn manure into power. The bedding is clean, soft and made up of plant fibers.

The Pikes also were the first farmers in Vermont and the Northeast to install a robotic milking system, which also was the first for a Jersey herd in the United States.

Les reports milk production has slowly improved as a result of the new system, “and the cows love the new system. It’s a great way to handle cows. They’re on their own schedule and we don’t bother them much. For cows, it’s a fantastic system.”

And what about for the farmer? Les explains expectations are a little high for any farmer choosing a robotic milking system. It does eliminate the physically taxing work of milking a herd twice a day, so a farmer is freed up to do other work, but Les and his crew are still in the barn, attending to other chores, with an emphasis on herd health.

Cows are fed a total mixed ration of haylage (forage that is baled at a higher moisture content than dry hay and then stored in a sealed plastic wrap) high-moisture shell corn and protein mix. The Pikes grow all their own grass and alfalfa on 135 acres, getting a yield of four tons of dry matter per acre. To improve cow comfort, they opened the side walls of their free-stall barn to provide natural ventilation and installed comfortable rubber floors and automatic alley scrapers to remove manure promptly.

It’s a far cry from the old farm of 90, 80 — heck, even 20 years ago, but as Les points out, constant improvement is not only the family motto, it’s the smart way to farm.